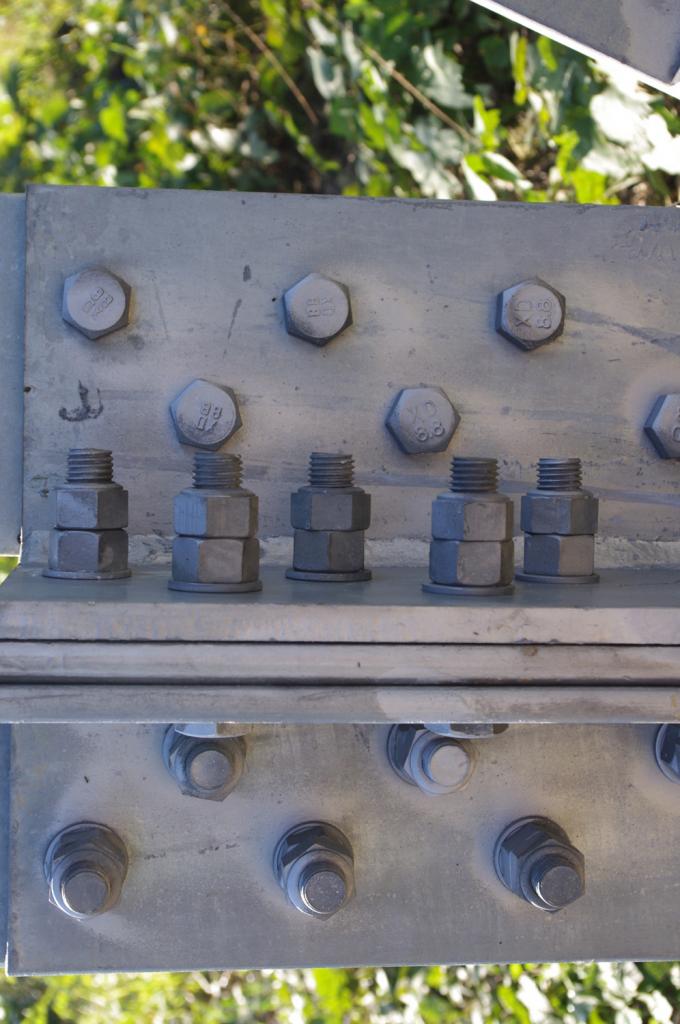

High Strength Hexagon Head Bolt Electric Fastener

| Name: | Galvanized Hexagon Bolts | Certificate: | ISO9001/CE/ROHS |

|---|---|---|---|

| Brand: | LJ | Surface Treatment: | Hot Dip Galvanized |

| High Light: |

Hexagon Head Bolt Electric Fastener, ISO9001 Hex Bolt Electric Fastener, Steel Towers Galvanized Hexagon Bolts |

||

High Strength Hot Dip Galvanized Hexagon Bolts For Uhvehv Transmission Line Steel Towers

Our tower bolts were designed specifically for cell towers, power transmission towers, and radio tower assemblies, whether they are applied to modifications, upgrades, or repairs. Tower’s bolts are corrosion-resistant and customized so you know you’re using the right bolts on every project, and that they’ll stand the test of time.

all products are in hot dip galvanized surface treatment mostly using for transmission line steel tower projects. size can be from M12-M105 , the bolts can be different shapes including the bolts. U bolts,anchor bolts.V-bolts etc.

High strength hexagon bolts, which are made of high-strength steel or need to apply large preload, can be called high-strength bolts. High strength bolts are mostly used for the connection of bridges, rails, high-pressure and ultra-high-pressure equipment. The fracture of this kind of bolt is brittle fracture. High strength bolts applied to ultra-high pressure equipment need to be prestressed to ensure the sealing of the container. Today, advanced manufacturing represented by large aircraft, large power generation equipment, automobiles, high-speed trains, large ships and large complete sets of equipment will enter an important development direction. Therefore, fasteners will enter an important stage of development. High strength bolts are used for the connection of important machinery. Repeated disassembly or various installation torque methods have high requirements for high strength bolts. Therefore, the quality of its surface condition and thread accuracy will directly affect the service life and safety of the host. In order to improve the friction coefficient and avoid corrosion, seizure or jamming during use, the technical requirements stipulate that the surface shall be treated with nickel phosphorus plating. The coating thickness shall be within the range of 0.02 ~ 0.03mm, and the coating shall be uniform, dense and free of pinholes.

Bolt material: 18Cr2Ni4W, 25Cr2MoV steel; Bolt specification: M27 ~ M48. Because this kind of steel is easy to form a passive film on the surface, and this passive film will make the bolt unable to obtain the chemical nickel phosphorus layer with good adhesion, special pretreatment measures must be taken to remove the film first, and measures should be taken to prevent its regeneration, so as to ensure good adhesion between the plated coating and the substrate. At the same time, the large geometric size of the bolt increases the difficulty of nickel phosphorus plating treatment and quality detection in the process. The process flow of nickel phosphorus plating for high strength bolts consists of three parts:

The first part is the pretreatment process, including precision and appearance inspection before plating, manual degreasing, soaking degreasing, pickling, electroactivation and flash nickel plating of high-strength bolts;

Part II electroless nickel plating process;

The third part is the post-treatment process, including hydrogen drive heat treatment, polishing and finished product inspection. As follows:

Chemical composition inspection of bolts → accuracy and appearance inspection of bolts before plating → manual degreasing → appearance inspection → immersion degreasing → hot water washing → cold water washing → acid pickling → cold water washing → electro activation → cold water washing → flash nickel plating → cold water washing → deionized water washing → chemical nickel plating → deionized water washing → cold water washing → hydrogen drive → polishing → finished product inspection.