ISO9001 Heat Resistant Steel Wire Splicing Sleeves

| Name: | Splicing Sleeve JY, JT, JYD Series | Certificate: | ISO9001/CE/ROHS |

|---|---|---|---|

| Application: | Transmission Line Conductor | Brand: | LJ |

| Material: | Aluminium | Feature: | Heat Resistant |

| High Light: |

Steel Wire Splicing Sleeves, Heat Resistant Wire Splicing Sleeves, ISO9001 Wire Splicing Sleeves |

||

Splicing sleeve JY, JT, JYD series

The splicing sleeve is used for the connection of the transmission line conductor and the connection under the full tension of the wire, the matching insulation cover is used for the connection of the overhead insulated wire in the overhead power line.

• The product is suitable for steel core aluminum stranded wire, steel stranded wire, aluminum stranded wire, aluminum alloy stranded wire, aluminum alloy cored aluminum stranded wire, heat-resistant steel core Connection tubes for aluminum alloy stranded wire, aluminum clad steel core aluminum alloy stranded wire, aluminum clad steel stranded wire, etc.and overhead insulated steel core aluminum stranded wire;

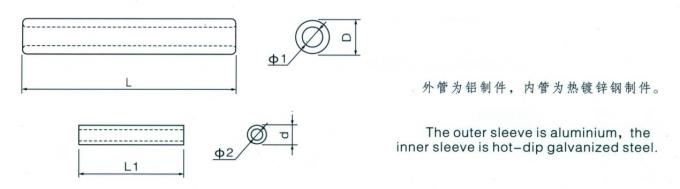

• The outer sleeve is aluminium, the inner sleeve is hot-dip galvanized steel;

Technical data sheet

|

Catalog No. |

Suitable Steel Wire |

Dimensions |

Slip Strength |

Weight |

|||||

|

D |

d |

L |

L1 |

Φ1 |

Φ2 |

||||

|

JYD-150/35 |

LGJ-150/35 |

36 |

22 |

380 |

100 |

25.5 |

18.5 |

61.8 |

0.64 |

|

JYD-185/25 |

LGJ-185/25 |

38 |

20 |

400 |

90 |

27.0 |

11.2 |

56.5 |

0.83 |

|

JYD-185/30 |

LGJ-185/30 |

32 |

20 |

372 |

82 |

21.0 |

12.0 |

61.0 |

0.62 |

|

JYD-185/45 |

LGJ-185/45 |

40 |

24 |

430 |

110 |

28.0 |

14.0 |

76.2 |

0.82 |

|

JYD-300/15 |

LGJ-300/15 |

40 |

18 |

470 |

70 |

24.5 |

8.4 |

65.0 |

0.89 |

|

JYD-300/20 |

LGJ-300/20 |

40 |

18 |

490 |

60 |

25.0 |

9.8 |

72.0 |

0.91 |

|

JYD-400/20 |

LGJ-400/20 |

45 |

18 |

550 |

80 |

28.5 |

9.8 |

84.0 |

1.24 |

|

JYD-300/25 |

LGJ-300/25 |

40 |

20 |

480 |

90 |

25.5 |

11.2 |

79.0 |

0.95 |

|

JYD-400/25 |

LGJ-400/25 |

45 |

20 |

550 |

90 |

28.5 |

11.2 |

91.0 |

1.30 |

|

JYD-240/30 |

LGJ-240/30 |

36 |

20 |

460 |

100 |

23.0 |

12.0 |

72.0 |

0.87 |

|

JYD-400/35 |

LGJ-400/35 |

45 |

22 |

540 |

100 |

28.5 |

13.0 |

99.0 |

1.79 |

|

JYD-500/35 |

LGJ-500/35 |

52 |

22 |

620 |

100 |

31.5 |

13.0 |

114.0 |

2.82 |

|

JYD-240/40 |

LGJ-240/40 |

36 |

20 |

440 |

100 |

23.0 |

13.3 |

79.0 |

0.97 |

|

JYD-300/40 |

LGJ-300/40 |

40 |

20 |

490 |

100 |

25.5 |

13.3 |

88.0 |

1.30 |

|

JYD-500/45 |

LGJ-500/45 |

52 |

24 |

610 |

110 |

31.5 |

14.0 |

122.0 |

2.88 |

|

JYD-630/45 |

LGJ-630/45 |

60 |

24 |

690 |

110 |

34.5 |

14.0 |

141.0 |

3.80 |

|

JYD-300/50 |

LGJ-300/50 |

40 |

22 |

490 |

120 |

26.0 |

15.0 |

98.0 |

1.21 |

|

JYD-400/50 |

LGJ-400/50 |

45 |

24 |

570 |

120 |

29.5 |

15.4 |

117.0 |

1.87 |

|

JYD-720/50 |

ACSR-720/50 |

60 |

24 |

715 |

120 |

38.5 |

15.4 |

162.0 |

4.00 |

|

JYD-240/55 |

LGJ-240/55 |

36 |

22 |

470 |

120 |

24.0 |

16.0 |

97.0 |

1.10 |

|

JYD-630/55 |

LGJ-630/55 |

60 |

26 |

680 |

120 |

36.0 |

16.0 |

156.0 |

3.63 |

|

JYD-800/55 |

LGJ-800/55 |

65 |

26 |

780 |

120 |

40.0 |

16.0 |

182.0 |

4.65 |

|

JYD-300/60 |

LGJ-300/60 |

42 |

24 |

525 |

130 |

27.0 |

16.5 |

114.7 |

2.60 |

|

JYD-400/65 |

LGJ-400/65 |

48 |

26 |

560 |

130 |

29.5 |

17.2 |

129.0 |

2.28 |

|

JYD-500/65 |

LGJ-500/65 |

52 |

26 |

640 |

130 |

32.5 |

17.2 |

146.0 |

2.93 |

|

JYD-300/70 |

LGJ-300/70 |

42 |

24 |

520 |

130 |

27.0 |

18.0 |

122.0 |

1.48 |

|

JYD-800/70 |

LGJ-800/70 |

65 |

26 |

760 |

130 |

40.5 |

18.0 |

197.0 |

4.50 |

The steel wire is connected to the casing, the connecting end of the steel bar is processed into threads (referred to as the thread head), and the two steel bars with the thread head are connected according to the specified torque value into an integrated steel joint through the threaded connection sleeve